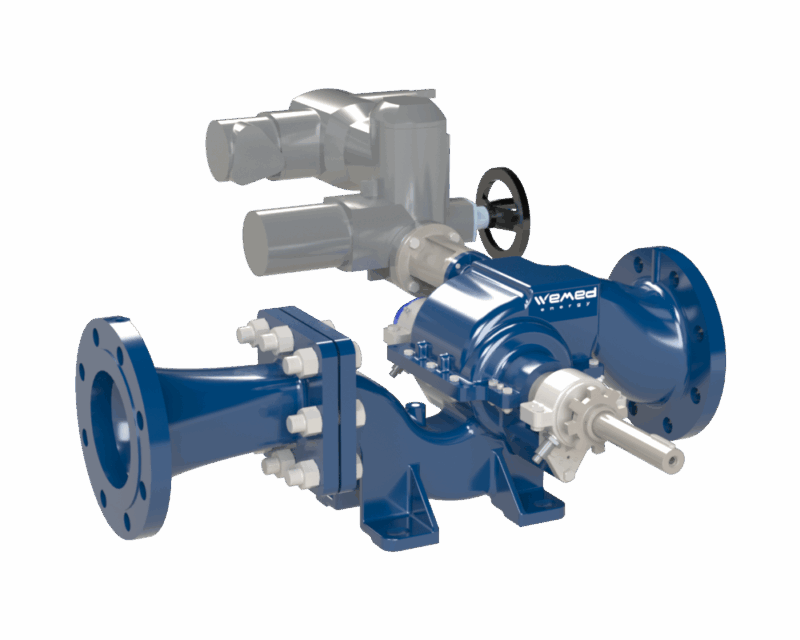

Components and technical advantages of the PRS System

PRS (Power Recovery System) is a patented, compact, modular system designed to operate inline within pressurized water networks, recovering energy that would otherwise be wasted.

It consists of a set of mechanical and electronic components, assembled to ensure reliability, efficiency, safety and compatibility with all existing water systems, meeting the demands of modern automation.

Main components of the PRS

The PRS is designed to deliver maximum efficiency, operational reliability and service continuity, even under complex hydraulic conditions.

By combining high-quality mechanical components with advanced electronic management, the system ensures high performance and low operating costs.

All PRS turbines are built to stringent construction standards and are specified according to the nominal diameter of the inlet and outlet pipes, with flanges aligned on a single axis. Developed to meet the demands of water distribution, the system is engineered to guarantee optimal performance. The components that make up the PRS turbine comply with regulations for materials in contact with drinking water and are of high quality.

Functional components

- Stainless steel runner and shaft

- High-precision bearings sized for the application

- Cast iron casing coated with reinforced epoxy resin

- High-efficiency control mechanism, with electric or hydraulic actuation

- Actuator that operates the internal regulation system (slider), modulating pressure or flow rate in real time

- Negative brake or suitable valves to ensure continuity of water supply even in the event of electrical grid disconnection

According to the installation site requirements or the specific needs of the client, the PRS system can also be equipped with:

- Inverter to handle upstream pressure changing during time

- Advanced sensors for safety, remote diagnostics and predictive maintenance

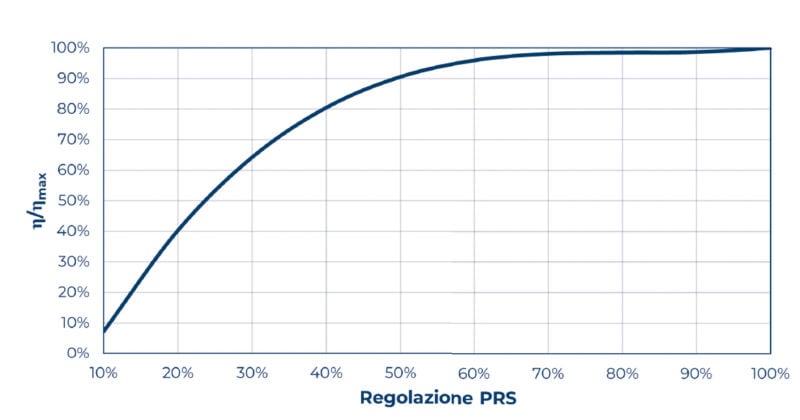

Operating range

The PRS turbine is designed to ensure stable and efficient renewable electricity generation, even under significant variations in flow rate and pressure. Thanks to its integrated control mechanism, the system continuously optimizes the operating point, maintaining high efficiency across a wide operational range.

PRS models

| Model | Head range ΔH (m) | Flow rate range (l/s) | Power range (kW) | RPM range | Face to face dimensions (mm) |

|---|---|---|---|---|---|

| D150 | 35-55 | 25-70 | 10-30 | 1500 | 900 |

| D200 | 20-95 | 40-160 | 10-100 | 750-1500 | 1200 |

| D250 | 20-95 | 50-200 | 10-150 | 500-1500 | 1500 |

| D300 | 10-95 | 65-350 | 10-250 | 375-1000 | 1800 |

| D400 | 10-95 | 140-500 | 15-450 | 375-750 | 2000 |

| D500 | 10-100 | 200-700 | 30-500 | 200-750 | 3000 |