PRS – Power Recovery System

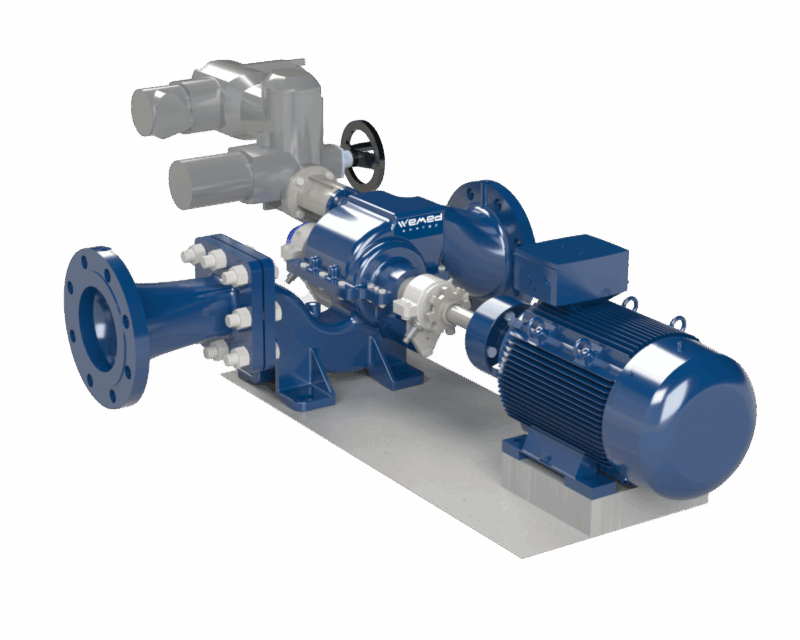

PRS (Power Recovery System) is an innovative technology designed to generate clean electricity directly from water networks, using a patented hydraulic turbine. By merging the functions of pressure-control valves with those of a turbine, PRS transforms excess hydraulic energy – usually wasted – into zero-emission power, without consuming land or water resources.

Developed by WECONS, the system enables real- time control of network hydraulic parameters (pressure and flow), ensuring the smooth operation of water services. At the same time, it generates affordable renewable electricity and unlocks new value from both existing and new water infrastructure.

A smart, efficient, and safe solution

Compatible with drinking water

Compliant with regulations for contact with drinking water

Smart and autonomous system

Long distance control with automatic regulation, not requiring on-site human assistance

Real-time monitoring of hydraulic parameters

(flow rate, pressure, etc.) and electrical parameters (power, energy production, etc.)

High and constant efficiency

Even under variable hydraulic conditions

Patented system

Manufactured to high production standards

Minimized investment costs

Short payback period due to easy integration into existing structures or simple new constructions

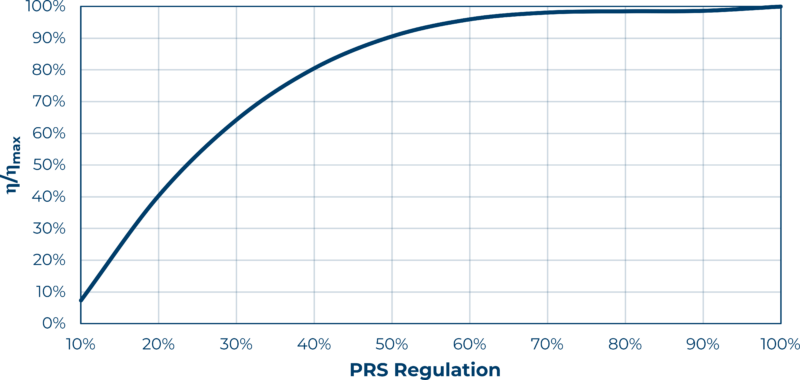

Compared to PATs (Pumps as Turbines) or turbines without a regulating unit, the PRS ensures higher energy production even under variable hydraulic conditions, thanks to its efficient integrated regulating unit.

Advantages

Unlike conventional solutions, such as Pump-as Turbine (PAT) systems or turbines without control mechanisms, the PRS:

- Maximizes recoverable energy through integrated automatic modulation

- Dynamically adapts to the pressure and flow conditions of the network

- Eliminates abrupt efficiency drops even under significant hydraulic fluctuations

The result is a substantially higher annual electricity production, enabling shorter payback periods and a genuine contribution to the energy transition.

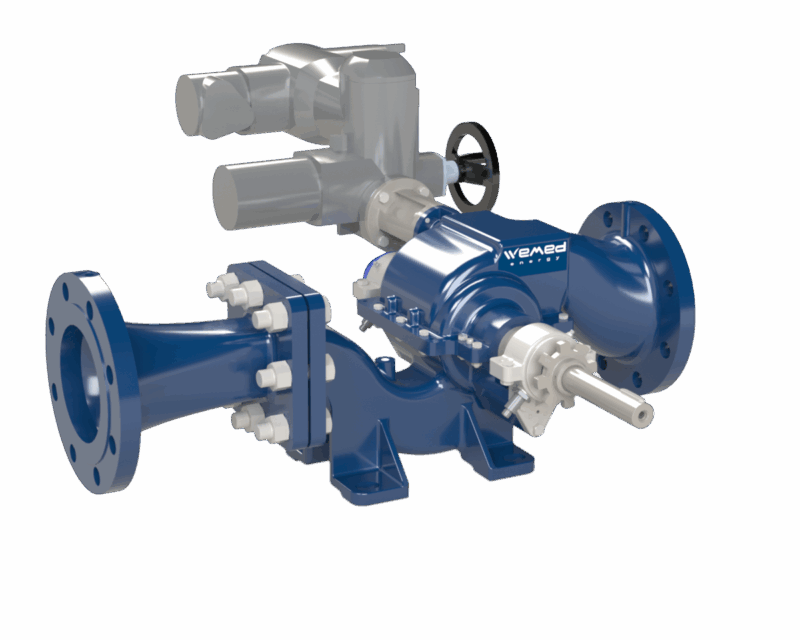

PRS is installed in a bypass line. This allows:

- controlled reduction of excess pressure even in the case of occurring extraordinary flow rates;

- generation of electricity never interfering with the water service, still achieving an annual production-to-installed capacity ratio far superior to other renewable energy sources;

- replacement of traditional control valves (needle vale, PRV, etc.), by harvesting the energy potential of existing infrastructure, still maintaining the same water management rules;

- continuous monitoring of hydraulic parameters, for a better knowledge of the hosting infrastructure and the service scenario;

- great flexible installation, with the PRS available in various nominal diameters and pressure classes. Its design for integration into the water system, combined with careful planning, enables the optimization of existing structures or spaces already available to the water network operator.

Overview of the main PRS characteristics

- Compatible with drinking water and compliant with regulations for materials in contact with drinking water;

- Smart and autonomous system with remote control and automatic regulation,

not requiring on-site human assistance; - Real-time monitoring of hydraulic parameters (flow rate, pressure, etc.) and electrical parameters (power, energy production, etc.)

- High and constant efficiency even under variable hydraulic conditions;

- Patented system manufactured to high production standards.

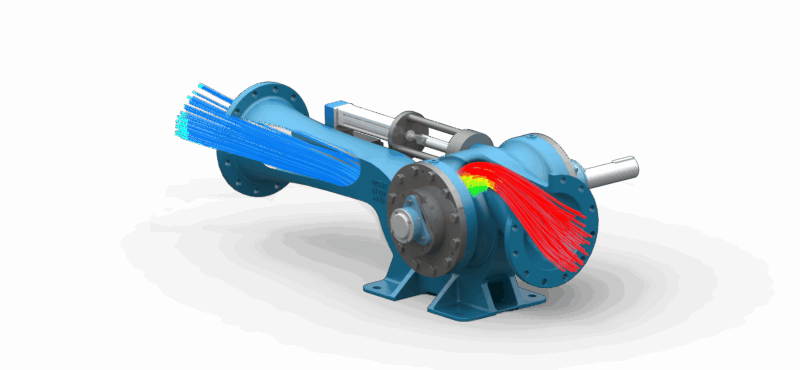

The pressurized cross-flow turbine

The PRS turbine is the result of years of research, experimental testing, and fluid dynamic simulations conducted also in collaboration with the University of Palermo, leading to the development of a product with unmatched technological maturity.

The heart of the system is the pressurized cross-flow turbine, designed to operate efficiently even under wide variations of flow rate and pressure, as typically occurring in water supply networks. The core of the PRS device is the cross-flow turbine, enhanced with a specially developed regulation unit, aimed to provide the sought after functional characteristics of control valves (Q – P). This design combines high performance, structural simplicity, and operational reliability.

The inline PRS turbine combines the functions of regulation valves (pressure and flow rate control) with that of hydraulic turbines (energy generation), converting the exceeding hydraulic energy – normally dissipated by valves – into clean, zero-CO₂ electrical energy.